|

Automated optical digital linearity deviation meter

Korolev À.N., Lukin A.Ya., Polishchuk G.S.

Measurement of deviations from linearity, flatness and alignment is the

important aspect of technologies, relating to mechanical engineering, aircraft industry

and shipbuilding. Besides, said measurement is widely used while controlling

the quality of plates, guiding elements of machines, frames of engines of large

dimensions, rolling mills, presses and turbines. Moreover, this type of

measurement is used to check linearity of moving of parts of machines as well

as of other mechanisms.

The Alignment Monitoring System, in which

automatic reflectivity design [1] is implemented, is known. If we apply this

system, the limiting value of allowable root-mean-square deviation (“RMS

deviation” below), relating to a random component of the basic error does not

exceed 0.05 mm at any distance up to 10 m.

Besides, Laser Linearity Deviation Meter

[2] has been developed. The basic feature of this meter is that it includes

axicon, used for forming the laser beam ring structure, which is convenient

when making measurements. Measurement of co-ordinates is performed by taking

into account position of the ring structure central spot, diameter of which is

some times less than the diameter of the laser beam. Measurement error is

determined by the accuracy of measurement of the central spot co-ordinates at

the speckle-sound background. Value of error may be determined by using the

formula ± (0,004 + 3·10 – 3 L), where L

is the distance in meters.

Another device, used for measurement of

deviations, is known under the name “PPS-11 Measuring Sighting Telescope”. This

device is intended to measure linearity deviations, relating to long objects,

as well as to measure alignment deviations, relating both to holes and tubes.

Moreover, said device is used for performing evaluation of non-parallelism,

extent of absence of perpendicularity and deviation from horizontal position,

which relate to surfaces of various articles. “LOMO” PLC was engaged in

manufacturing this optical instrument some years ago, and at present said

instrument is widely used at the mechanical engineering, machine-tool building

and shipbuilding plants for carrying out accurate measurements of linearity

deviations.

Such instruments, which are known under the

name “Alignment Telescopes”, are manufactured by some companies of other

countries. For example, optical devices, produced by the “Taylor Hobson”

company of Great Britain [5], have a very high reputation.

An alignment telescope includes objective

lens and focusing lens, which are employed to form image of a measuring mark in

the plane of cross hairs. Said measuring mark may be located at any of the

distances, lying within the range 0 – 30 meters, from the telescope end face.

It is assured that whenever the focusing lens is moved in longitudinal

direction it is moving along the guiding line without any deviations. In this

way the required position of the sighting line with respect to the optical axis

of the system, including objective lens and focusing lens, is maintained. Value

of misalignment of the optical mark image with respect to the sighting line is

measured by means of the optical micrometer, which includes tilting

plane-parallel plate and measuring drums. Position of these drums is changing

while the plane-parallel plate is being turned around two mutually

perpendicular axes. Operator monitors alignment by viewing image in the device

ocular.

When performing measurements an operator

should bring an image of the measuring mark into focus within the alignment

telescope. To achieve focusing an operator must move focusing lens by using

special control handle. Then misalignment of the measuring mark image with

respect to the sighting line is subject to measurement. This measurement is

performed by way of turning the plane-parallel plate around the horizontal axis

and the vertical axis as well as by bringing the mark image centre and the

cross hairs centre into perfect coincidence. It should be noted that quantity

of measurements depends upon the distance between the measuring mark and the

telescope end face. If said distance exceeds 10 meters then measurement should

be carried out not less than 10 times.

The main disadvantages of such optical instruments

are insufficient accuracy of measurements and low productivity of an operator’s

labour, that is caused by great number of operations, performed manually.

The digital device of OPTRO-PPS-031 type

[6], intended to measure linearity deviations by means of sighting the

measuring mark, was developed. Said meter includes the digital TV-camera, which

functions as a photo-detector. Both processing of data bulk, relating to

TV-images, and controlling all the procedures of measurement are performed by way

of using the corresponding software.

In the digital device, presented here, the

function of a photo-detector is carried out by the BR-1340LM-UF type digital

TV-camera (www.es-experts.ru). This camera includes the

CCD-matrix of dimension 5,7 mm x 6,3 mm (number of pixels is 1280 x 1024, the

pixel size is 5,2 micron x 5,2 micron).

In Fig.1 the side view of the digital meter

alignment telescope and the shape of the measuring mark are shown.

Fig. 1

The measuring mark is a transparent

element, on the surface of which circles of various diameters, relating to a

single centre, are drawn. This mark is illuminated by means of a light diode

matrix. The software database employs the table, which includes such data as circle

consecutive numbers, circle diameters and relative width of rings, located

between adjacent circles. Values of the circle diameters are presented by a

functional, which allows both to calculate some values of relative width of

rings and to apply these values for automatic determining a circle consecutive

number. The measuring mark shape affords an opportunity for carrying out

measurements within the range 0 – 30 meters. If distance is short then

measurement is performed by way of using image of the central circles of small

diameters. If distance is long image of the circles of small diameters may not

be formed, and that is why measurement is performed by way of using image of

the circles of large diameters.

Applying the measuring mark of the maximum

diameter 90 mm affords the opportunity for performing measurements at the

distance 30 meters. Provided the diameters of the mark peripheral circles are

large enough the distances, at which measurements are performed, may be as long

as 50 or even 100 meters. The most important limiting factors in this case are

stiffness of a measuring stand and environment stability.

Block diagram of the digital device, which

is used to measure both the linearity deviations and the alignment deviations,

is shown in Fig. 2. This diagram includes the following elements: measuring

mark 1, provided with illuminator; object, such as frame, plate, slab, guiding

element etc., subject to measurement; the main objective lens 3; the focusing

lens 4; optical system 5, which forms an inverted image; digital TV-camera 6;

control block 7; computer 8, to which TV-camera 6 and control block 7 are

connected. The block 7 controls functioning of the drive, which provides

step-by-step movement of the focusing lens 4. The term “drive, providing

step-by-step movement” means aggregation of a step-by-step engine and a

mechanism, which are employed to convert rotational movement of said engine

into the focusing lens translation.

Fig. 2

When the process of measurements is being

carried out the measuring mark images are located in different positions on a

surface of an object under study. These positions correspond to the route,

along which measurements should be performed, and they are located at various

distances from the deviation meter.

Focusing of the lens 4 at the measuring

mark image is carried out after the computer generates the corresponding

command, that leads to movement of said lens. While the focusing lens is moving

each of the frames, formed by the TV-camera, is used to calculate the focusing

parameter. Value of this parameter is determined by the sum of the first

derivative magnitudes, relating to all points of a 2-D array, used to display

the measuring mark. The process of automatic focusing is completed at the

moment the maximum value of the focusing parameter is obtained.

As a result of performing the above

mentioned process values of both the focal distance and the image scale are

subject to change.

According to the software, employed to

carry out measurements, the following procedures, relating to each of the

measuring mark positions, are performed:

a) automatic throwing the measuring mark

image into focus with respect to the TV-camera matrix surface;

b) determining an image scale or, to be

exact, the optical system magnification (by way of measuring the diameters of

circles, by comparing the measured values with their nominal values and by

calculating the weighted mean value);

c) establishing the value of distance to

the measuring mark (by way of using the tabulated database, which refers image

scale to determined distance);

d) ascertaining position of the measuring

mark image centre on the matrix surface (by way of measuring the image centre

co-ordinates with respect to each of the circles as well as by determining the

weighted mean value with respect to the circles, subject to examination);

e) calculating the value of misalignment of

the measuring mark image centre in relation to co-ordinates of the sighting

line trace;

f) calculating the value of misalignment of

the measuring mark centre in the object space with respect to the base-line.

The term “sighting line trace” means the

point where the sighting line intersects the plane of the TV-camera light

sensitive matrix.

Performing each of the abovementioned

procedures is based on digital processing of the measuring mark image, formed

on the matrix surface. It should be noted that the digital processing methods

offer averaging different results of a measurement. Specifically, the following

results may be subject to averaging:

1) the results of a measurement of

the centre co-ordinates for each of the frames, formed by the TV-camera (this

averaging relates to those circles, which are displayed due to imaging the

measuring mark);

2) the results of a single

measurement conformably to predetermined number of frames;

3) the results of a measurement

conformably to predetermined number of single measurements;

4) the results of measurements

in conformity with the predetermined number of focusing positions.

Applying digital processing methods allows

yielding very accurate result of measurements as well as to estimation of value

of a random error, which presents the quality of measurements.

Below the following equation symbols will

be used:

L – distance from the deviation meter to the measuring mark in meters;

X, Y – co-ordinates of the mark image

centre along the axes X and Y in microns according to the scale of co-ordinates

of the light sensitive matrix;

dX, dY – deviation of a component profile

from the base line in microns relative to the co-ordinates X and Y;

V – magnification of an objective lens in relative units.

Let us consider calculation of profile of a

component, subject to measurement, which is carried out by taking into account

linearity deviation from the Y-axis.

Provided the process of measurements yields

the results for N points, located on

the distance scale, the component profile co-ordinates in each of n measurement points (n = 1 … N) should be determined by using the equation

Pn = (Yn– Yc) · Vn , (1)

In

this equation Ycis the

co-ordinate of the sighting line trace within the detecting TV matrix. (The

procedure of determining the co-ordinates of the sighting line trace within the

light sensitive matrix of a TV-camera will be considered below).

The basic purpose of performing the

measurements is to define a component profile relative to base-line, by means

of which the initial point and the final point are located with reference to

the co-ordinates P1 and PN . That is why co-ordinates

of the base line should be determined

, (2) , (2)

And only then by using the equation (3)

the profile co-ordinates relative to the base line may be determined

dYn = Pn– Bn, (3)

The results of measurements of the rail profile co-ordinates are

included in the table 1 for illustration. The measurements were performed in

the mode, which may be outlined in the following way: bringing the objective

lens into focus (5 times) – carrying out 5 measurements each time the objective

lens is brought into focus – forming 5 frames relative to each of the measurements.

It is obvious that measurement information, used for each of the profile

points, contains 125 frames.

The table 1 includes the following additional equation symbols:

sdX –

average value RMS deviation, relating to dX (in microns);

sdY – average value RMS deviation,

relating to dY (in microns);

sX – average value RMS

deviation, relating to X (in microns);

sY – average value RMS

deviation, relating to Y (in microns);

sV – average value RMS

deviation, relating to V (in relative

units).

Table 1

Results of measurements of the article profile

| n |

L, ì |

dX, ìêì |

dY, ìêì |

sdX, ìêì |

sdY, ìêì |

X, ìêì |

Y, ìêì |

sX, ìêì |

sY, ìêì |

V |

sV |

| 1 |

1.608 |

0 |

0 |

0.3 |

0.3 |

3396.50 |

2357.17 |

0.06 |

0.07 |

3.9406 |

0.0001 |

| 2 |

1.71 |

24.1 |

-71.5 |

1.0 |

0.6 |

3398.76 |

2403.06 |

0.19 |

0.14 |

4.1378 |

0.0001 |

| 3 |

1.813 |

4.4 |

-131.6 |

0.7 |

0.3 |

3390.71 |

2448.32 |

0.16 |

0.06 |

4.335 |

0.0003 |

| 4 |

1.918 |

-15.8 |

-157.3 |

0.5 |

0.4 |

3383.19 |

2497.81 |

0.11 |

0.09 |

4.5312 |

0.0005 |

| 5 |

2.023 |

8.4 |

-158.2 |

0.1 |

0.1 |

3385.70 |

2548.91 |

0.02 |

0.03 |

4.7264 |

0.0002 |

| 6 |

2.13 |

40.8 |

-128.0 |

0.4 |

0.3 |

3389.64 |

2602.85 |

0.08 |

0.07 |

4.9217 |

0.0005 |

| 7 |

2.236 |

59.7 |

-78.0 |

0.2 |

0.3 |

3390.65 |

2656.38 |

0.04 |

0.06 |

5.1144 |

0.0005 |

| 8 |

2.344 |

74.8 |

-25.9 |

0.6 |

0.5 |

3390.84 |

2707.14 |

0.11 |

0.10 |

5.309 |

0.0008 |

| 9 |

2.45 |

67.4 |

36.4 |

0.5 |

0.7 |

3386.99 |

2755.61 |

0.09 |

0.12 |

5.4996 |

0.0003 |

| 10 |

2.558 |

30.0 |

83.6 |

0.4 |

0.4 |

3378.07 |

2798.56 |

0.07 |

0.08 |

5.6919 |

0.0004 |

| 11 |

2.664 |

18.1 |

117.5 |

0.4 |

0.3 |

3374.09 |

2836.31 |

0.07 |

0.04 |

5.8834 |

0.0004 |

| 12 |

2.771 |

-41.0 |

129.0 |

0.5 |

0.4 |

3362.61 |

2867.81 |

0.08 |

0.08 |

6.0739 |

0.0006 |

| 13 |

2.877 |

-23.4 |

128.6 |

0.8 |

1.3 |

3364.07 |

2895.48 |

0.13 |

0.21 |

6.2649 |

0.0002 |

| 14 |

2.982 |

-24.1 |

110.1 |

0.4 |

0.7 |

3362.61 |

2918.40 |

0.07 |

0.11 |

6.4537 |

0.0005 |

| 15 |

3.087 |

-6.0 |

85.4 |

0.4 |

0.4 |

3364.06 |

2939.10 |

0.06 |

0.07 |

6.643 |

0.0002 |

| 16 |

3.193 |

11.0 |

47.3 |

0.8 |

1.2 |

3365.27 |

2957.00 |

0.12 |

0.19 |

6.8344 |

0.0006 |

| 17 |

3.299 |

0 |

0 |

0.4 |

1.0 |

3362.43 |

2972.36 |

0.06 |

0.14 |

7.0235 |

0.0006 |

The results,

presented in the Table 1, indicate that the average value RMS deviation,

relating to co-ordinates (sX, sY) of

the measuring mark image centre, does not exceed 0.2 microns. When the distance

is changed within the range 1.6 – 3.3 m the average value RMS deviation,

relating to the results of measurements (sdX,

sdY), does not exceed 1.5 microns. If we consider the value sV, presented in the Table 1, it becomes

obvious that the value of error, which takes place when distance L to the

measuring mark is being determined, is in the order of 1 mm.

By performing experimental measurements at long distances (in the order

of 30 metres) it was proved that the average value RMS deviation, relating to

co-ordinates (sX, sY) of the mark

image centre, practically does not change when the distance is changed. As to a

first approximation magnitudes (sdX, sdY)

and (sX, sY) are related to the value

of magnification V. This statement is

confirmed by the data, presented in the table. If the distance to the measuring

mark is equal to 30 metres then the magnification value amounts to 50X. That is

why magnitudes (sdX, sdY), measured

at the distance 30 metres, may be equal to 10 microns, that is confirmed by the

results of measurements. Besides, if distances are in the order of 30 metres,

then error of distance measurement does not exceed 10 mm.

By considering the data, given above, it may be concluded that the

accuracy of measurement, provided by the OPTRO-PPS-031 digital meter, is by an

order of magnitude greater than the accuracy, provided by the PPS-11 optical

device.

As a rule the measurement errors, inherent in the sighting devices, are

estimated by determining the difference between the results of measurements,

made for two positions of a device. In the first of these positions device axis

and measurement sighting telescope axis coincide, while in the second position

a device is swung relative to a sighting telescope axis by 180 degrees.

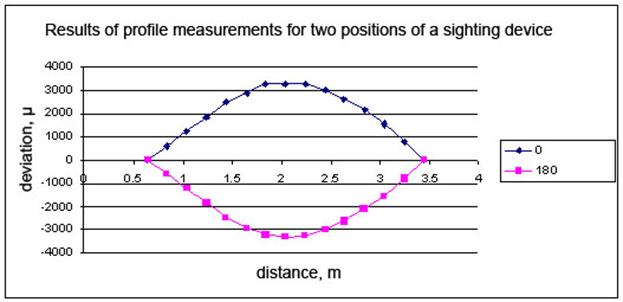

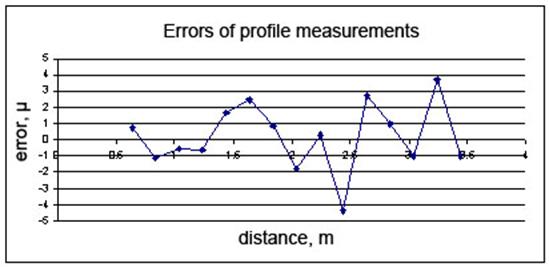

Fig. 3

Graphs, constructed in Fig. 3, are useful in visualising the results of

profile measurements, relating to two abovementioned positions of a device, as

well as the error of measurements for each of the profile points, subject to

measurement. Said errors are estimated by determining the difference of results

of measurements, relating to two positions of a device. In both of the graphs,

constructed in Fig. 3, quantities of measurement distance in metres are plotted

on X-axis, while quantities of deviation from the base line in microns are

plotted on Y-axis of the upper graph, and error quantities in microns are

plotted on Y-axis of the lower graph. It may be seen that within the distance

range 0.7 – 3.5 metres the value of error does not exceed some microns.

As relating to the measurement process, described here, the basic

systematic error is the error of co-ordinates of the sighting line trace. If

distance values are great the basic systematic error practically has no

influence on the measurement process. That is why only those measurements,

which are performed at small distances, are of the greatest interest in the

field of metrology.

If one uses an optical device he must set a measurement cross hairs on a

device optical axis by way of alignment. And if one uses a digital meter,

presented here, he does not need to set a light sensitive matrix central point

on a device optical axis. It should be noted that setting a matrix central

point on a device optical axis is impossible due to the fact accuracy of

measurement of location of a measuring mark centre is as high as some fractions

of micron. Below is considered the simple method of determining co-ordinates of

a sighting line trace on a light sensitive matrix surface. This method includes

two runs of measurements of a component profile. When the first run of

measurements is performed digital device axis and sighting telescope axis

coincide, while during performing the second run of measurements a device is

swung relative to the sighting telescope axis by 180°. While making

calculations, relating to two versions of a component profile, the co-ordinates

of a sighting line trace remain common for each of the profile versions. The

summation with respect to all profile values is made (it should be noted that

the profile co-ordinates, relating to the abovementioned device positions, are

of opposite signs). Then one strives for minimisation of sum of the profile

values by way of selection the co-ordinates of the sighting line trace. This

procedure is executed without any difficulties by using the “Excel” program.

Calculated values of co-ordinates of the sighting line trace are entered into

the program database for the purpose of performing computations when the

digital meter is used.

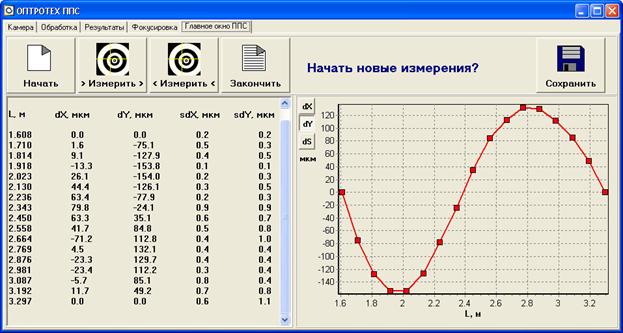

It should be pointed out that generating both the measurement protocol

and the graph of deviations of the mark centre from the base line is started by

the digital meter since the moment the measurement, relating to the third point

of the measurement route, is performed. The first point and the second point of

this route relate to the base line. Result of each of the subsequent

measurements is presented both in the protocol and the graph immediately.

Recalculation of data, relating to the base line, takes place any time a new

short-range or long-range end point appears. That is why while the measurement

cycle is being performed points may be arranged in any order. The final

measurement protocol and the graph, which presents a component profile, are

drawn up in the real-time mode, and drawing up of these documents finishes at

the moment the command “Complete” is generated. Generation of this command

takes place after the measurements, relating to the last one of the points,

have been performed (see Fig. 4).

Fig. 4

According to the instructions for use of the optical devices duration of

the process, needed to process the results of measurements, to calculate the

base line and to determine the profile deviations, is as long as 30 minutes. By

taking into account this fact anyone may become firmly convicted that capacity

of the digital meter is much greater than capacity of any optical device.

Reference list:

1. Anisimov A.G., Aleev A.M., Pantyushin A.V., Timofeev A.N., Basic errors of alignment control, revealed by using the automatic

reflection opto-electron system, “Optics Magazine”, volume 76, # 1, 2009, p.

3–8.

2. Pinaev L.V., Leontieva G.V., Butenko L.N., Seriogin A.G., Laser meter, used to determine error in linearity, Patent of the

Russian Federation # 2457434, 2010.

3. Apenko M.I., Araev V.A., Afanasiev V.A., Dureiko G.V., Zakaznov

N.P., Romanov D.A., Usov V.S., Optical devices,

used in the field of machine manufacturing, Reference Book, “Mashinostroenie”

Publishers, 1974, p. 120–167.

4. Danilevich F.M., Nikitin V.A., Smirnova E.P., Assembly and alignment of optical instrumentation, “Mashinostroenie”

Publishers, 1976, p. 222– 241.

5. Prospectus of the “Taylor

Hobson” company (www.taylor-hobson.com)

6. Koroliov A.N., Lukin A.Ya., Malinin S.M., Polishchuk G.S., Tregub

V.P., Digital meter, used to determine errors in

linearity and alignment, Patent of the Russian Federation # 112396, 2012.

|