New concept of angle measurement; Simulation and experimental studies

Korolev À.N., Lukin A.Ya., Polishchuk G.S.

Among great number of known precision converters

and angle measuring instruments, optical-electronic devices with rasterization

and code conversion are the most perfect ones. Those types of measuring

instruments are produced in Russia (SKB IS [1]) as well as abroad (HEIDENHAIN

GmbH (Germany) [2] and RENISHAW (Great Britain) [3]).

In such angular optoelectronic raster converters

radial or cylindrical raster scale which is read by the analyzer made in a form

of a raster as well is used as angular measures. For the precise convertors the

amount of lines in the raster reaches few hundreds of thousands when the spacing

between the lines equals to few micrometers. Therefore the dimensions of glass

disks with raster scale are 20-30 sm. Due to the high requirements to stability

of positional relationship of analyzer and measuring raster the convertor need

to be mounted on the high precision spindle using precision or air pressure

bearings.

For accuracy level of few seconds of arc and less

the principal limitation of such devices are:

- large scale and weight;

- limitations of measurement accuracy

due to backlash and vibration influence;

- high cost.

The objective of this paper is the description of

new concept of angle measurements, based on measurement of rotation angle of a target

(represented as an ordered set of single-type elements) image, relative to the

rectangular coordinate system of rows and columns of digital camera

photodetector [4], and also the analysis of some results of simulation and

experimental study of new measurement technology.

Let us formulate the main distinct peculiarities of new angle

measurement concept.

First of all, it is the transfer from analysis of 1D raster scale to

analysis of 2D information field which requires brand-new design concepts and

data processing technology. The important factor here is the high level of

averaging of target elements coordinates that is proportional to M2,

where M is the number of elements in the measuring field, since calculation of

weight-average coordinates is performed for M elements along the X axis and for

M elements along Y axis. The total number of elements in analyzed field can

reach few hundreds.

Secondly, due to the high level of averaging, measuring system becomes

extremely tolerable to such destabilizing factors as detector noise and etc. As

a result the new measurement technology has high resolution that allow us to

use small size measuring field. Therefore, the measurement error on the level

of 1 second of arc can be obtained on the light-sensitive array with dimension

less than 10 mm. Which is almost two orders smaller than dimension of raster

sensors.

Thirdly, as a consequence of new technology there is no connection of

angle measurement results to rotation axis. It is obvious that any transversaltranslational

displacements will not change the results of angle measurement. This effect

makes the new technology essentially different from well-known technologies

described above.

Fourthly, it should be noted that new angle meter can be certified via

standard with its further mounting on the measuring object which is impossible

for raster convertors mentioned above.

In the fifth place, the possibility of target images synthesis with any

random rotation angle with high precision allow us to obtain angle standards in

the form of digital files. This is completely new case in metrology. But in a

sense there is no contradiction in this. Because, unlike majority of

measurands, angle, by definition, is dimensionless value.

All listed above characteristics and capabilities taken together allow

us to speak about new conception of angle measurement that can serve as the

basis for development of wide class of rather simple, compact and reasonably

priced sensors and plane angle meters with different purposes and accuracy

level.

It is worth mentioning that for this

technology number of measurements per unit time is determined by frame

frequency of TV camera. Therefore, in order to increase operation speed,

high-speed TV cameras with high frame frequency should be used.

Fig. 1

Scheme of

angle measurement device that illustrates the new conception is represented on

the fig.1. Optical target 2 with the lamp rotates along with rotor 1 and is

imaged by the lens 3 on the photodetector of digital camera 4 and then is send

to the computer 5, which performs conversion and data processing, ensuring

determination of target rotation angle relative to photodetector array.

The optical target configuration is a 2D set of

elements with known positioning, for example, orthogonal grating composed of

circle elements with relative brightness 1 on the background with relative

brightness 0.

Due to the fact that orthogonal grating has rotation symmetry for

certain angles (0, 90, 180 and 270 degrees), labels that uniquely determine

target orientation are required. Three elements of the target that have larger

diameter than other ones form scalene triangle. The position of this triangle

is used for determination of grating orientation and ensures measurement range

0-360î.

It is obvious, that by increasing the number of elements in the array

and dimensions of digital camera photodetector we can obtain the higher

measurement accuracy. At the same time, element dimensions (the circle

diameter) determines the accuracy of element coordinate determination and by

decreasing it we decrease accuracy. The optimal configuration involves a

certain compromise between elements diameter and array spacing.

It is obvious, that in current scheme target can be set even at

considerable distance from rotor rotation axis.

In this paper we do not discuss sensor design, optimal parameters of the

target and peculiar algorithms of video data processing and transformation that

are designed to obtain the angle magnitude.

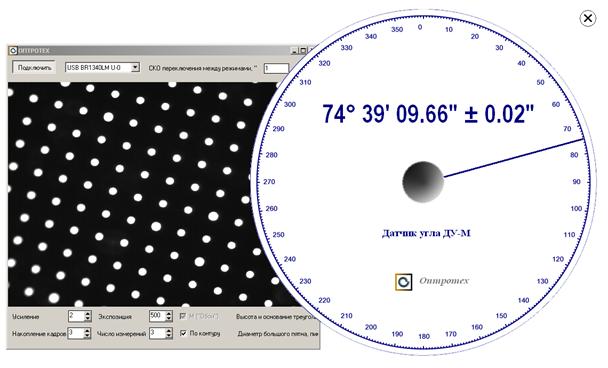

Fig.2 shows angular scale of experimental angle measuring instrument

alongside with measurement result and software program panel with elements of

data input and measurement process control, that include image of optical

target. As a radiation detector we used TV camera BR-1340LM-UF [5] with 5.7 by

6.3 mm CMOS*) matrix (1280õ1024 pixels, one pixel 5.2õ5.2 mkm),

lens magnification equals to 1.

Fig. 2

On the bottom of program panel you can see input windows: “Accumulation

of frames” – 3, “number of measurements” – 3. This means that for single

measurement we need to carry out the accumulation of three frames. In order to

receive the result presented on the dial plate we used three measurements. When

more than one measurement is used we need to calculate the MSE of measurement

result. The MSE is then shown on the dial plate near measured angle value as

“± 0.02"”. For multiple metering in the same angular position during about

one minute, repeatability of measurements amounted to 0.08".

Quite a number of factors affect measurement result. However, the affect

of such characteristics of detector as nonlinearity of light characteristic,

dark noise, photon noise, irregularity of pixels sensitivity, charge spreading

(blooming) and etc. can be minimized with the help of different algorithmic

tools.

In this case, main factors that determine measurement error are

quantization noises and anisotropic distortion of the lens, which lead to the

deterministic shifts of some elements of the target. Since sampled digital

image of the target is a picture of overlap of two periodic structures

(periodic structure of target elements and structure of light sensitive array),

resonance beat patterns appear in certain positions that lead to elements displacements

and tempering of measurement results. These deterministic shifts make essential

contribution to the measurement error and even can give isolated spikes out of

3σ,

where σ is MSE of random deterministic measurement error in the measurement range 0-360î. These

spikes can be reduced by implementation of stochastic deviation of target

geometry with regard to elements diameter and spacing between them. This

variant was successfully tested during model studies.

Peak value of lens distortion in the experimental prototype of angle

measurer on the edge amounted to just few microns. For the target with periodic

structure of elements precise measurement of lens distortion can be easily

conducted. Such magnitude of distortion lead to the measurement constant error

in each point of angular scale, and its peak value can reach 10-15 seconds of

arc. Use of optics with higher quality can significantly reduce this error

fraction, and in the case of zero distortion exclude it at all.

Metrological certification of experimental prototype of angle meter was conducted using Measuring Rotary table (MRT) which uses raster method of

angle measurement and holographic angular scale with raster spacing about 1 mkm

and diameter 180 mm. MRT was made in the Laboratory of informational-measuring

systems of B.P.Konstantinov Petersburg Nuclear Physics Institute RAS [6]. This device is used in the

Laboratory of angular measurements D.I. Mendeleev Russian National Research

Institute of Metrology as a part of National Angle Standard, its estimated

accuracy is about 0.2 seconds of arc.

At first we conducted the calibration of angle-meter in the range 0-360î in

increments of 1 degree. Received set of points describes constant error of

angle-meter, associated with distortion. This smooth enough function is carried

into the software memory and allows to implement correction in any point of the

scale. Cubic interpolation is conducted in order to calculate the correction

value inside 1 degree intervals.

Fig. 3

Graph 3 represents the deviation of readings of experimental prototype

of angle meter from mentioned above standard angle measuring device in the

range 0-360 degrees with correction of constant error taken into account.

Standard deviation of single measurement error is 0.25", peak deviation is

about 1".

It is rather complex to experimentally determine optimal target

configurations and limiting metrological capabilities of this new measurement

technology during the study.

Therefore it became obvious, that it is necessary to develop

mathematical model of angle measurement device with target image generator for

any possible rotation angle and standard for such meter algorithm of target

image processing and angle calculation. The development of software for target

image generation is interesting also in connection with the possibility of

developing the digital angle standards for this technology in the form of image

files.

For the correct and complete description of target image in the

simulation program, generator should take into account the following

parameters: 1) size of photodetector matrix in pixels, 2) diameter of target

elements, 3) target array spacing, 4) lens modulation transfer function, 5)

noises of photodetector matrix, 6) number of frames used for averaging of

results for single measurement, 7) number of measurements used for averaging in

order to receive final measurement result.

The influence of the distortion was not taken into account in this

model.

The main problem of developing a new model was the generation of sampled

image of the target for arbitrary angle. It is rather difficult to generate

such data array based on the analytical description of the array elements with

the help of bit-by-bit integration. Therefore we applied, used in the work [7],

method of generation of sampled target elements with fractional center of

gravityshift

relative to the array of readings.

Let the x0n,k, y0n,k be the coordinates of

circular aperture centers along gratings rows n and columns k for rotation

angle α =

0. Center coordinates after rotation by the arbitrary angle α were

calculated according to well-known formula of coordinates transformation:

(1). (1).

After division of center coordinates by pixel size of specific CCD

(CMOP) matrix we obtain coordinates values in fractions of pixel

After division of center coordinates xαn,k and yαn,k of the element with number n,k by pixel size of CMOP matrix we

obtain coordinates values in fractions of pixel. The integer part of received

values determines the position of this element in the sampled image of the

target, while the fractional part is used to synthesize the image of this

element with the center of gravity shift by the fraction of a pixel.

Synthesis of discrete model of each target circular aperture consisted

of the following operations:

1. Calculation of object's

Fourier spectrum

, (3) , (3)

where ω is the spatial frequency, Ô is direct Fourier transform. Object f(x,y) is a

circle of chosen diameter with relative brightness 1 on the background with

relative brightness 0.

2. Calculation of the image

spectrum, which was shifted and blurred by the lens, according to the following

formula:

, (4) , (4)

where exponential factor is a phase shift, which ensures shift of the object by Δx and Δy that

correspond to fractional part of the coordinates xαn,k and yαn,k, H(ωx,ωy)

is the lens modulation transfer function (MTF), calculated according to

well-known formula for diffraction-limited system:

, (5) , (5)

ωmax is cutoff spatial frequency of MTF.

3. Calculation of the digital array, which corresponds to the circular aperture image, shifted

relative to the array of readings by a given value of Δx and Δy,

, (6) , (6)

where  is an

inverse Fourier transform. is an

inverse Fourier transform.

After quantization (f.e. 256 levels for 8 bit per pixel) and

normalization the obtained image of each element is inserted into corresponding

area of digital data array, that describes the complete picture of target

discrete image.

It is worth mentioning that inaccuracies of production (generation) of

target itself as well as limited number of quantization levels is the reason of

coordinate error in the form of arbitrary shift of each element relative to

ideal array of target elements for both generated target image and target image

received from digital camera in real-time. Hence follows the high requirement

to the accuracy of target making and to the number of quantization levels and

photodetector noises.

Discussed technology of target image generation for arbitrary rotation

angle involve calculation of M direct and inverse Fourier transforms where M is

the number of elements in the target. Simulation experiments for great number

of elements which include target synthesis and its measurement are

computationally intensive.

During this study we analyzed rather large amount of choices of combined

parameters of optical target but we can hardly say that the absolutely optimal

alternatives were found.

Developed model offers a possibility to investigate parameters of

desired signal for threshold angular displacements of target image. If the

measurement field is limited by the circle with diameter slightly less than

matrix diagonal, i.e. 8 mm, and rotation center is in the middle of the matrix,

extreme elements of the target while rotation to the 360î travel over

distance equal to the perimeter of circle 8 π = 25 mm. Since one complete angle contains 1296000 seconds of arc while

rotation to the 1 second of arc image of extreme elements moves over a distance

of 20 nm. And what happens with target image?

Let us take the difference between two modeling images of the target

with angular displacement equals to 1 second of arc. Computation results show

that on the edge of the elements (circular apertures) that have peak value of

displacement for about 10-12 pixels we receive difference of 1 quantizing

level, that is illustrated in the fig.4 on the magnified picture of absolute

value of images difference with normalization on full brightness. It should be

noted that on the one side of the elements (in the direction of rotation) we

obtain change of +1 quantizing level and on the other side -1 quantizing level.

The fragment presented on the fig. 4 correspond to the left upper corner of the

target image; rotation axis direction approximately through the right down

corner. In order to maintain experiment integrity image generation was

conducted without noise overlap.

Fig. 4

We conducted three different variants of virtual measuring experiment

with estimation of absolute measurement error as a difference between angle

values calculated using target images synthesized by generator and rated values

of target rotation angle for generation of its image; basic experiment

parameters are presented in the table 1.

Table 1

| Experiment

version |

Matrix

size, pixels |

Pixel

size, mkm |

Number

of target elements |

Lens

resolution, mm-1 |

Photodetector

noise, quantizing levels |

Number

of measurements |

| 1 |

1280õ1024 |

5.2 |

357 |

50 |

1 |

3 |

| 2 |

3000õ2200 |

3.5 |

825 |

70 |

1 |

3 |

| 3 |

5000õ2200 |

4.2 |

1971 |

70 |

1 |

3 |

The results of conducted virtual measuring experiments are presented in

the table 2.

Table 2

| Experiment

version |

MSE of measurement result error (σ)

seconds of arc |

Maximum error value (3 σ)

seconds of arc |

| 1 |

0.18 |

0.53 |

| 2 |

0.04 |

0.12 |

| 3 |

0.007 |

0.022 |

Modeling results for the variant 1 are well correlated with the results

of metrological certification of experimental angle meter. Modeling results for

the variants 2 and 3, for which the matrix with significantly larger dimension

were used, show that potential metrological possibilities of new concept of

angle measurement allow us to speak about accuracy level of hundredths of

second of arc.

Conclusions:

The results of experimental and simulation studies of estimation of

metrological characteristic of the angle meter designed according to the new

conception of angle measurement were described. The concept was developed by

the authors of the paper and is based on the determination of angular position

of image of optical target on the image sensor of TV camera using special data

processing algorithms. The mathematical model of angle meter that uses target

images generator with any rotation angle in rectangular coordinates and

standard for this angle-meter data processing algorithm was developed. Metrological

study of experimental prototype showed that error of angle-meter does not

exceed 1 second of arc. Simulation study showed that potential accuracy level

of new technology of angle measurement is hundredths of second of arc.

* CMOS Complementary-symmetry/metal-oxide-semiconductor.

References

1. Booklet of SKB IS company www.skbis.ru),

2. Booklet of HEIDENHAIN GmbH company (www.heidenhain.de)

3. Booklet of RENISHAW company (www.renishaw.com)

4. Korolev A.N., Lukin A.Ya., Polishchuk G.S., the Patent RU ¹ 109847 «Angle-Meter».

5. Booklet of ES-Experts» company (www.es-experts.ru)

6. S.V.Gordeev, B.G.Turukhano, Investigation of the interference field

of two spherical waves for holographic recoding of precision radial diffraction

gratings, Optics & Laser Technology, vol. 28, ¹ 4, p. 255-261.

7. Korolev A.N., Gartsuev A.I., Polishchuk G.S., Tregub V.P. Metrological studies and the

choice of the shape of an optical mark in digital measuring systems. Journal of

Optical Technology. Vol. 77 Issue 6. pp.370-372 (2010).

|